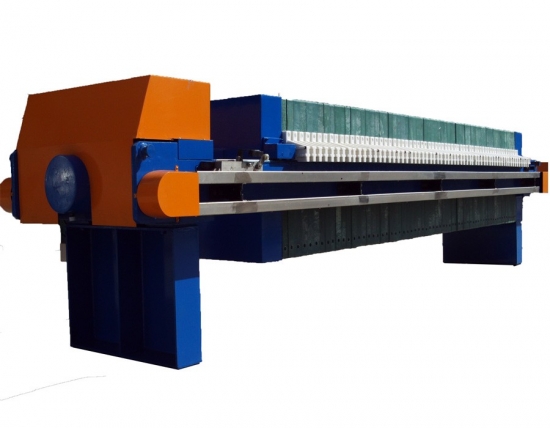

Sewage Recycling Machine Sludge Filtering Press Machine

The Sewage Recycling Machine Sludge Filtering Press Machine plays a vital role in enhancing the efficiency of sewage recycling. It is designed to handle the complex composition and high moisture content of sludge.

This machine ensures effective separation of solids and liquids in the sludge, reducing its volume and improving its dewatering performance. The advanced filtering technology and precise pressure control enable consistent and reliable operation.

It is widely used in sewage treatment plants and industrial wastewater treatment facilities, contributing to the reduction of environmental pollution and the reuse of resources. The durability and ease of maintenance make it a cost-effective choice for long-term operation.

Filter Press descriptions:

1. The main parts of filter press is made of high intensity welded steel, accessories processed by PLC with high precision.

2. The filter plates are made of PP, long life span Corrosion resistant, non-toxic and tasteless

3. Hydraulic Pressing, adopting the contact meter to maintain the pressure automatically.

4. The highest working pressure could be 1.5Mpa.

5. PLC control system, automatic open the plates one by one, open and close the water collector.

Filter Press Application:

Food, Chemical, Dyeing, Leather, Mining (Aluminium, Bauxite, Copper, Iron) and Electroplate.

Filter Press Technical Parameters:

Model | Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) L*W*H | Weight (kg) |

NX-800 | 50 | 800*800 | 60 | 1.5 | 50 | 750 | ≤1.0 | 4794*1246*1325 | 3140 |

60 | 60 | 900 | 5404*1246*1325 | 3470 |

70 | 70 | 1050 | 6014*1246*1325 | 3950 |

NX-1000 | 50 | 1000*1000 | 60 | 3.0 | 30 | 750 | ≤1.0 | 3984*1500*1555 | 4590 |

60 | 36 | 900 | 4350*1500*1555 | 4800 |

70 | 42 | 1050 | 4716*1500*1555 | 5160 |

80 | 48 | 1200 | 5082*1500*1555 | 5440 |

How Filter Press Work:

The slurry is sent by slurry pump to chambers which formed by filter plates. Then filtrating media (filter cloth) separates solid and liquid. After the filtration finished, stopping the feeding, releasing the slurry pressure, press the returning button, shifting the plates automatically.

FAQ

1.Q: Can you provide us the detailed drawing?

Yes, we can provide you the drawing after have made the prepayment.

2.Q: Are you a manufacturer or a trader?

We're a professional and experienced manufacturer located in Fujian province.

3.Q: Can you accept OEM?

Yes

4Q: How about the delivery time?

Normally 10-30 working days after prepayment, and we promise we will make the delivery as soon as we can.

English

English  français

français español

español português

português العربية

العربية Melayu

Melayu ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia

IPv6 network supported

IPv6 network supported