Solid Liquid Separation Machine Sludge Press Filtration

The Solid Liquid Separation Machine Sludge Press Filtration provides an efficient and reliable method for treating sludge. It is designed to handle the challenging task of extracting liquids from thick and viscous sludge.

This machine applies pressure to the sludge, forcing the liquid to be separated from the solid particles. The result is a significant reduction in the moisture content of the sludge, making it easier to handle and dispose of.

It is widely utilized in various industries, including wastewater treatment, chemical processing, and food manufacturing. The advanced design and robust construction ensure consistent performance and long-term durability.

With its ability to improve the sludge treatment process and minimize waste, the Solid Liquid Separation Machine Sludge Press Filtration is an essential tool for achieving efficient and environmentally friendly operations.

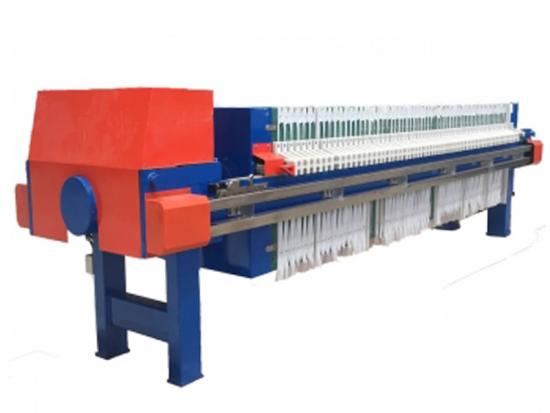

Filter Press descriptions:

1. Strengthen polypropylene filter plates and flame are made through mold pressing.

2.Adopt hydraulic pressing with the maximum pressure pressure of 25Mpa and automatic pressure maintaining by using electrical connecting pressure gauge.

3.PLC control system, automatic open the plates one by one, open and close the water collector.

high precision.

Filter Press Application

Textile, Food, Chemical, Dyeing, Leather, Mining (Aluminium, Bauxite, Copper, Iron) and Electroplate.

Filter Press Parameters:

Model | Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) L*W*H | Weight (kg) |

NX-800 | 50 | 800*800 | 60 | 1.5 | 50 | 750 | ≤1.0 | 4794*1246*1325 | 3140 |

60 | 60 | 900 | 5404*1246*1325 | 3470 |

70 | 70 | 1050 | 6014*1246*1325 | 3950 |

How Filter Press Work:

Feeding pump transports the slurry into the filter press from the feeding head, the chambers created by the plates are filled up with the slurry, the cloth (specifically developed for each material) and the high pressure dry the cakes, faster and better. The clean water is discharged into water collector, ready to be reused, and the cakes can now be disposed of easily.

Pre-sale service:

1.Your inquiry will be replied within 8 hours.

2.Help you to select suitable model

3. Spare parts are in stock

After-sale service:

1.Provide 12 months warranty period and you will have our technology support forever

2.Engineering available to offer the service to your machinery overseas

English

English  français

français español

español português

português العربية

العربية Melayu

Melayu ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia

IPv6 network supported

IPv6 network supported