The Sewage Treatment Water Filtering Machine Filtration Press is a specialized device tailored for filtering water in sewage treatment.This filter press is widely used in sewage treatment, such as dyeing, chemical, textile, mining and so on.

The Hydraulic Plate Chamber Slurry Filter Press is a specialized equipment designed for filtering slurry through a hydraulic-powered plate and chamber system.Square plate filter press could be of automatic plate shifter and automatic water collector, as your choice.

Lead Time:

according to the machine model and quantProduct Origin:

chinaShipping Port:

xiamenPayment:

T/T, LC at sightColor:

customizedHydraulic Plate Chamber Slurry Filter Press

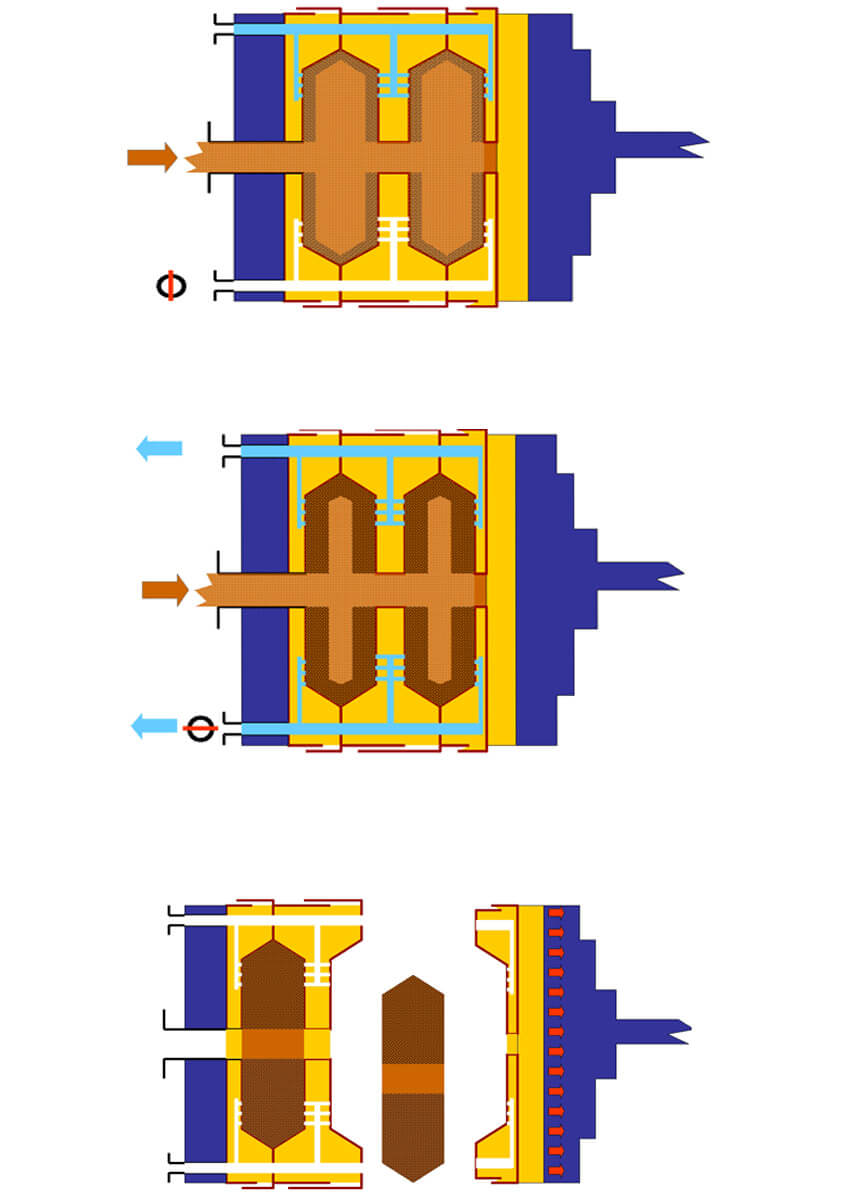

The Hydraulic Plate Chamber Slurry Filter Press provides an efficient and reliable method for separating solids from liquids in slurry. The hydraulic system ensures consistent pressure application, resulting in effective filtration.

This filter press is engineered to handle high volumes of slurry and is suitable for various industries such as mining, chemical, and wastewater treatment. The plate and chamber design allows for easy maintenance and replacement of filter media.

It helps to reduce the moisture content of the filtered solids, improving the overall processing efficiency and reducing waste. The robust construction and advanced control system make it a durable and user-friendly option for industrial filtration applications.

Filter Press descriptions:

1. The main parts of filter press is made of high intensity welded steel, accessories processed by PLC with high precision.

2. The filter plates are made of PP, long life span Corrosion resistant, non-toxic and tasteless

3. Hydraulic Pressing, adopting the contact meter to maintain the pressure automatically.

4. The highest working pressure could be 1.5Mpa.

5. The machine structure is simple and reasonable, easy installation and maintenance.

Filter Press Application:

Food, Chemical, Dyeing, Leather, Mining (Aluminium, Bauxite, Copper, Iron) and Electroplate.

Filter Press Technical Parameters:

Model

| Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) L*W*H | Weight (kg) |

NX-800 | 50 | 800*800 | 60 | 1.5 | 50 | 750 | ≤1.0 | 4794*1246*1325 | 3140 |

60 | 60 | 900 | 5404*1246*1325 | 3470 | |||||

70 | 70 | 1050 | 6014*1246*1325 | 3950 | |||||

NX-1000 | 50 | 1000*1000 | 60 | 3.0 | 30 | 750 | ≤1.0 | 3984*1500*1555 | 4590 |

60 | 36 | 900 | 4350*1500*1555 | 4800 | |||||

70 | 42 | 1050 | 4716*1500*1555 | 5160 | |||||

80 | 48 | 1200 | 5082*1500*1555 | 5440 |

Filter Press Working:

The slurry is sent by slurry pump to chambers which formed by filter plates. Then filtrating media (filter cloth) separates solid and liquid. After the filtration finished, stopping the feeding, releasing the slurry pressure, press the returning button, shifting the plates automatically.

Our company insists on the sprit of concentration, enterprising and excellence, continuously struggling and developing. We are sincerely expecting the cooperation with customers home and abroad, engaged in developing and strengthening environmental protection together.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.