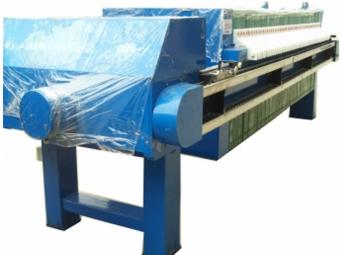

Sewage Treatment Water Filtering Machine Filtration Press

The Sewage Treatment Water Filtering Machine Filtration Press offers a highly effective and efficient solution for purifying sewage water. It is engineered with advanced filtration technology to handle the complex composition of sewage.

The filtration press works by applying pressure to separate impurities and contaminants from the water, resulting in cleaner and safer effluent. This machine is capable of handling large volumes of sewage and ensuring consistent filtration performance.

It is widely adopted in sewage treatment facilities, contributing to the improvement of water quality and the protection of the environment. Its reliable operation and low maintenance requirements make it a valuable asset in the field of sewage treatment.

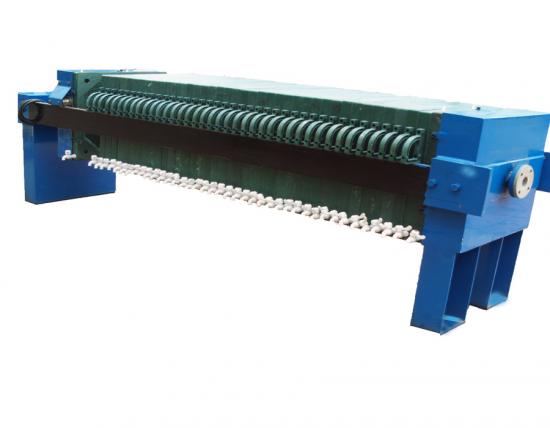

Filter Press Description:

1.Strengthen polypropylene filter plates and flame are made through mold pressing.

2.Adopt hydraulic pressing with

the maximum pressure pressure of 25Mpa and automatic pressure

maintaining by using electrical connecting pressure gauge.

Filter Press Application:

Square filter press are widely used in Food, Chemical, Dyeing, Leather, Mining Tails and Electroplate.

Filter Press Technical Parameters:

Hydraulic Chamber Filter Press With Square Plates

Model | Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) L*W*H | Weight (kg) |

NX-630 | 16 | 630*630 | 50 | 1.5 | 26 | 200 | ≤1.0 | 2790*1020*1200 | 1320 |

20 | 32 | 250 | 3096*1020*1200 | 1400 |

25 | 40 | 313 | 3504*1020*1200 | 1540 |

NX-800 | 50 | 800*800 | 60 | 1.5 | 50 | 750 | ≤1.0 | 4794*1246*1325 | 3140 |

60 | 60 | 900 | 5404*1246*1325 | 3470 |

70 | 70 | 1050 | 6014*1246*1325 | 3950 |

Plates could be added or reduced according to customer’s requirements.

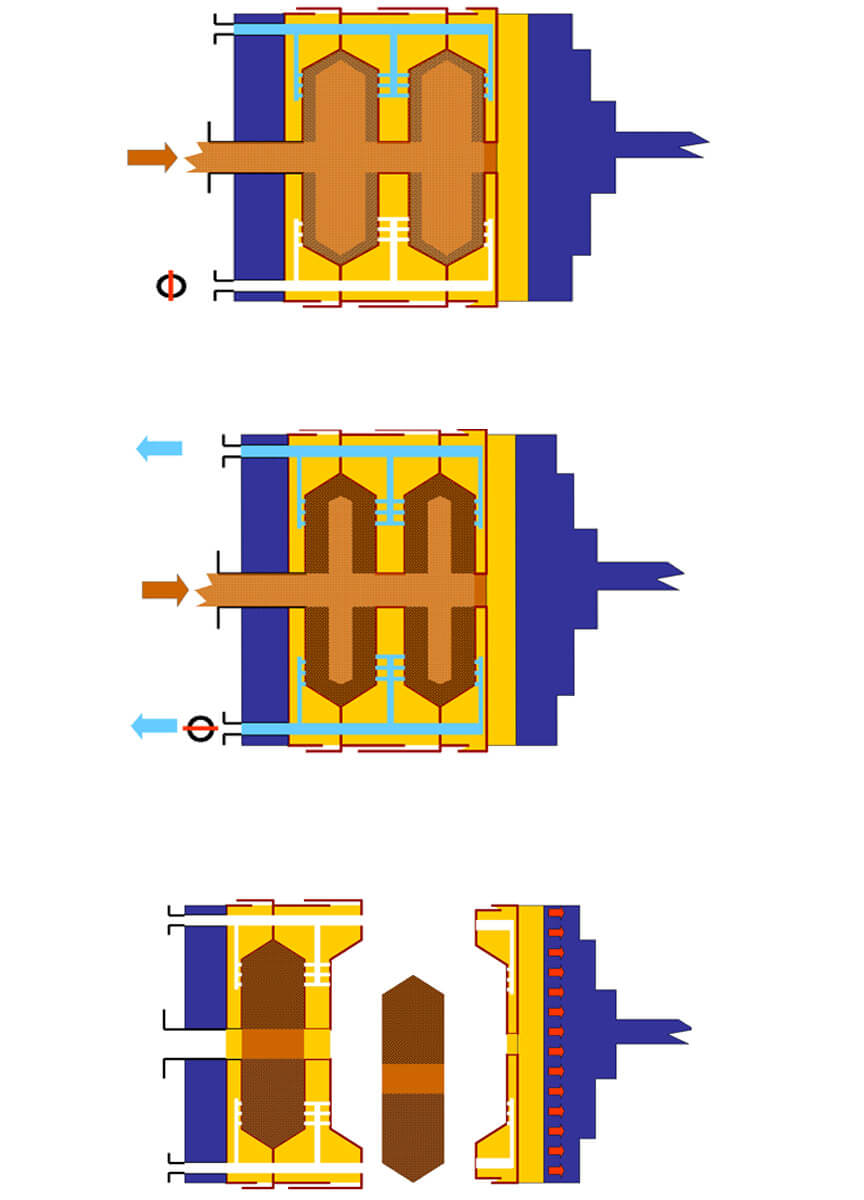

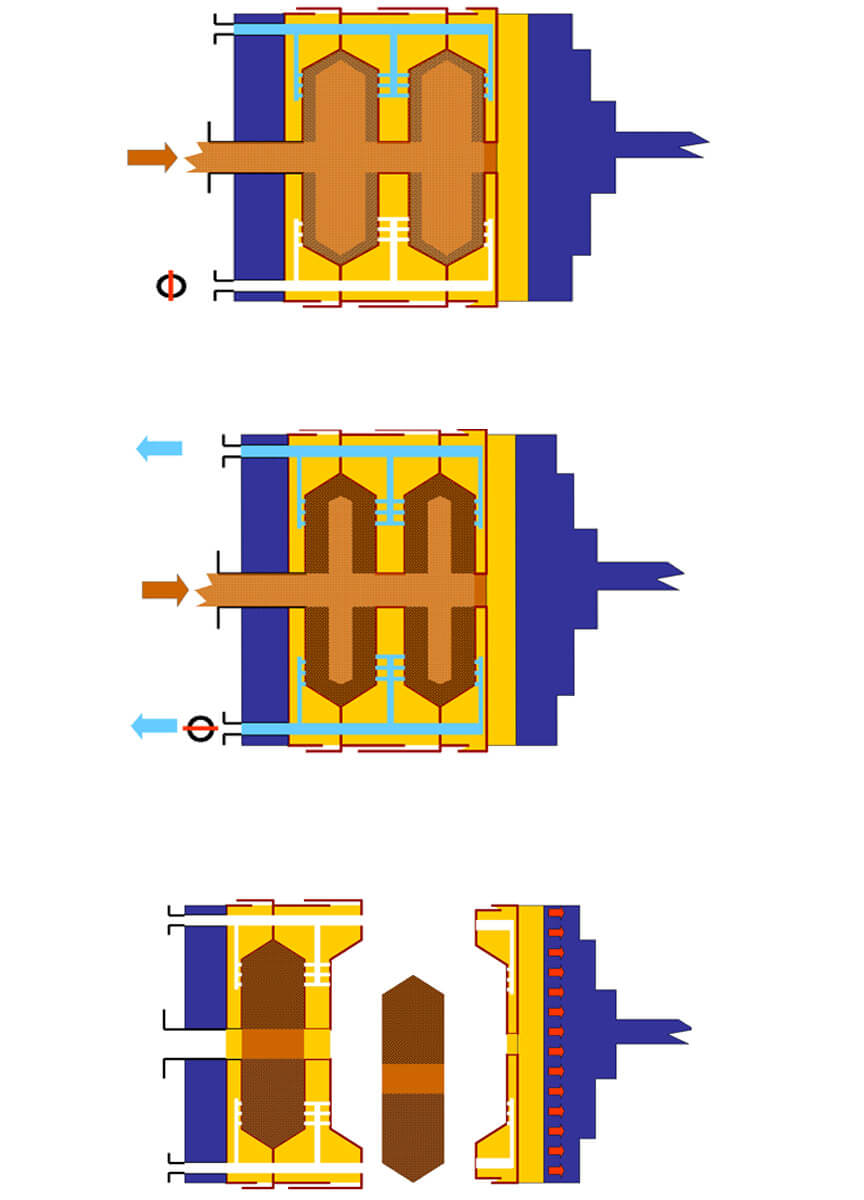

How Filter Press Work:

When

closing the filter press to pressure, the plates form chambers, the

sludge has been transported, the solids are retained in the chambers,

the liquid is evacuated through the exit orifices. When the chamber is

full, the water content decreases and a dry cake with the solid content

is formed.

About us:

In

2012, Relying on the advantages of Fujian Nan’an Machineries

manufacturing base and optoelectronic information industry base, we

founded Fujian Nanxing Environmental Technology Co., Ltd. invest heavily

for new factory and new equipments, put into use in 2014.

English

English  français

français español

español português

português العربية

العربية Melayu

Melayu ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia

IPv6 network supported

IPv6 network supported