The Small Manual Jack Sewage Sludge Press Filter is a compact and user-friendly device designed for the treatment of sewage sludge. It operates with a manual jack mechanism for easy and efficient sludge pressing.

The Automatic Fast Open Plate Shifter Hydraulic Chamber Circular Plate Filter Press is an advanced filtration device that combines automatic operation, fast plate shifting, and a hydraulic chamber with circular plates.

Lead Time:

According to size and quantityProduct Origin:

ChinaShipping Port:

XiamenPayment:

T/T, LC at sightAutomatic Fast Open Plate Shifter Hydraulic Chamber Circular Plate Filter Press

The Automatic Fast Open Plate Shifter Hydraulic Chamber Circular Plate Filter Press offers a highly efficient and convenient filtration solution. The automatic and fast plate shifting feature significantly reduces processing time and enhances productivity.

The hydraulic chamber ensures uniform pressure distribution for optimal filtration results. The circular plate design provides a larger filtration area and improved filtration efficiency.

This filter press is engineered with precision and durability in mind, making it suitable for a wide range of industrial applications. It simplifies the filtration process and lowers maintenance costs.

Whether in the mining, chemical, or wastewater treatment industries, this advanced filter press is a valuable asset for achieving high-quality filtration and efficient operations.

Filter Press Characteristic:

1. The main parts of filter press is made of cast steel, High strength, Stable Structure and long usage life.

2. The filter plates are made of high intensity HDPE, the highest working pressure could be 2.5Mpa, long life span and acid and alkali resistance.

3. Adopting the contact meter to maintain the pressure automatically, saving the labor cost and improve the working efficiency.

4. It is of automatic plate opening device, opening all the plates by one shift.

5. It is of automatic shaking device, discharging filtered cakes automatically

6. Customer could also choose the automatic water collector

How Filter Press Works:

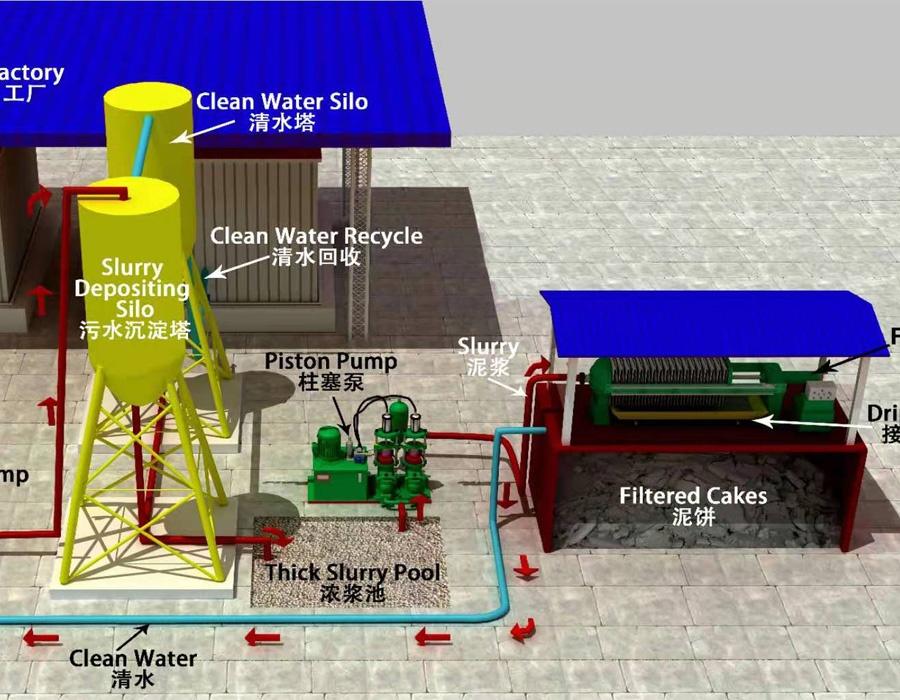

Ceramic plunger pump transports the slurry into the filter press from the feeding head, the chambers created by the plates are filled up with the slurry, the cloth (specifically developed for each material) and the high pressure dry the cakes, faster and better. The clean water is discharged into water collector, ready to be reused, and the cakes can now be disposed of easily.

Filter Press Application

Mining, Washed Coal, Waste water Treatment(Ceramic, marble, granite, glass and so on) , Kaolin, Clay, Sand Washing and other solid-liquid separation.

Filter Press Technical Parameters:

Model

| Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) | Weight (kg) | ||

L | W | H | |||||||||

KJWYB650-30 | 20 | 650 | 50 | 7.5 | 30 | 300 | ≤1.5 | 6800 | 1300 | 1200 | 4000 |

KJWYB1000-30 | 40 | 920 | 60 | 7.5 | 30 | 540 | 7700 | 1600 | 1500 | 6000 | |

Plates could be added or reduced according to customer’s requirements.

Other Introduction:

Our company could help customer to design wastewater treatment flow.

Our company is the main machineries supplier for clay project of Dalian Insulator Group Co., Ltd., Fujian Guanfu Modern Household Wares Co.,Ltd., Fujian Jinjiang Wanli Ceramics Industry Co., Ltd., Huihuang Plumbing Group Co. ,Ltd. etc. For the stone wastewater treatment, our company is also the tier one suppliers for stone wastewater treatment of Liven Stone, Xishi Group, Kangli Stone Group, Huahui Stone etc.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.