The Small Manual Jack Sewage Sludge Press Filter is a compact and user-friendly device designed for the treatment of sewage sludge. It operates with a manual jack mechanism for easy and efficient sludge pressing.

The Stone Sewage Treatment Slurry Filtration Machine is a dedicated device engineered for filtering and treating the slurry in stone sewage.

Lead Time:

according to the machine model and quantProduct Origin:

chinaShipping Port:

xiamenPayment:

T/T, LC at sightColor:

customizedStone Sewage Treatment Slurry Filtration Machine

The Stone Sewage Treatment Slurry Filtration Machine provides a crucial solution for the efficient management of stone sewage. It is designed to handle the specific challenges and characteristics of the slurry produced in the stone processing industry.

This filtration machine ensures effective separation of solids and liquids, reducing the pollutant content and facilitating the subsequent treatment or disposal of the treated water. Its advanced filtration mechanism and robust construction make it capable of withstanding the demanding operating conditions.

In stone processing plants and related facilities, the machine plays a vital role in maintaining environmental compliance and optimizing the overall sewage treatment process. It helps to minimize the environmental impact and promotes sustainable operations.

Filter Press Characteristic:

1. The main parts of filter press is made of cast steel, Stable Structure and long usage life.

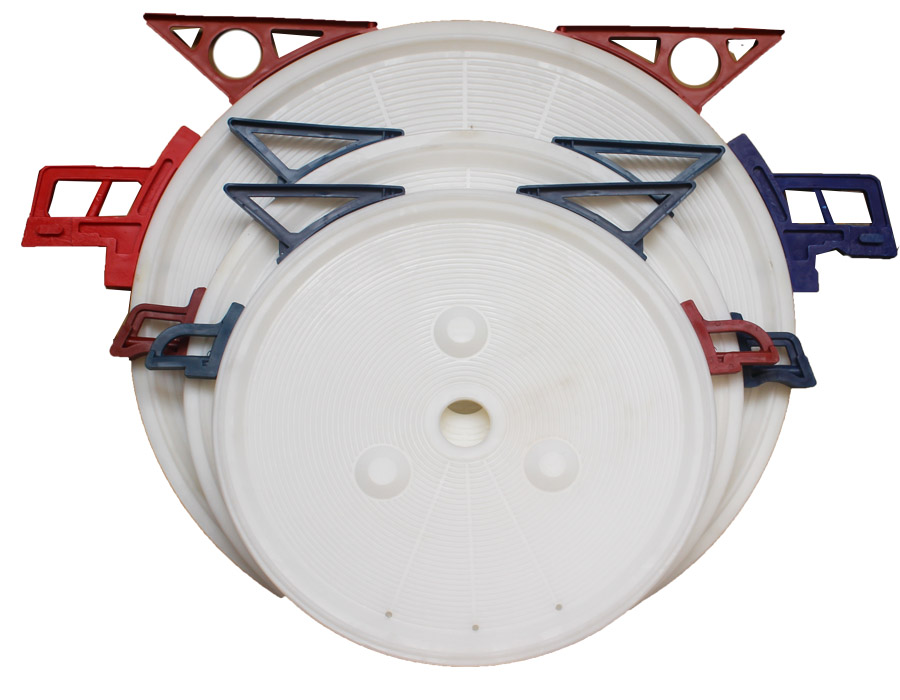

2. The filter plates are made of high intensity HDPE, the highest working pressure could be 2.5Mpa, long life span and acid and alkali resistance.

3. Filter plates has moutain and valley design, good for preventing slurry spout.

4. Adopting the contact meter to maintain the pressure automatically, saving the labor cost and improve the working efficiency.

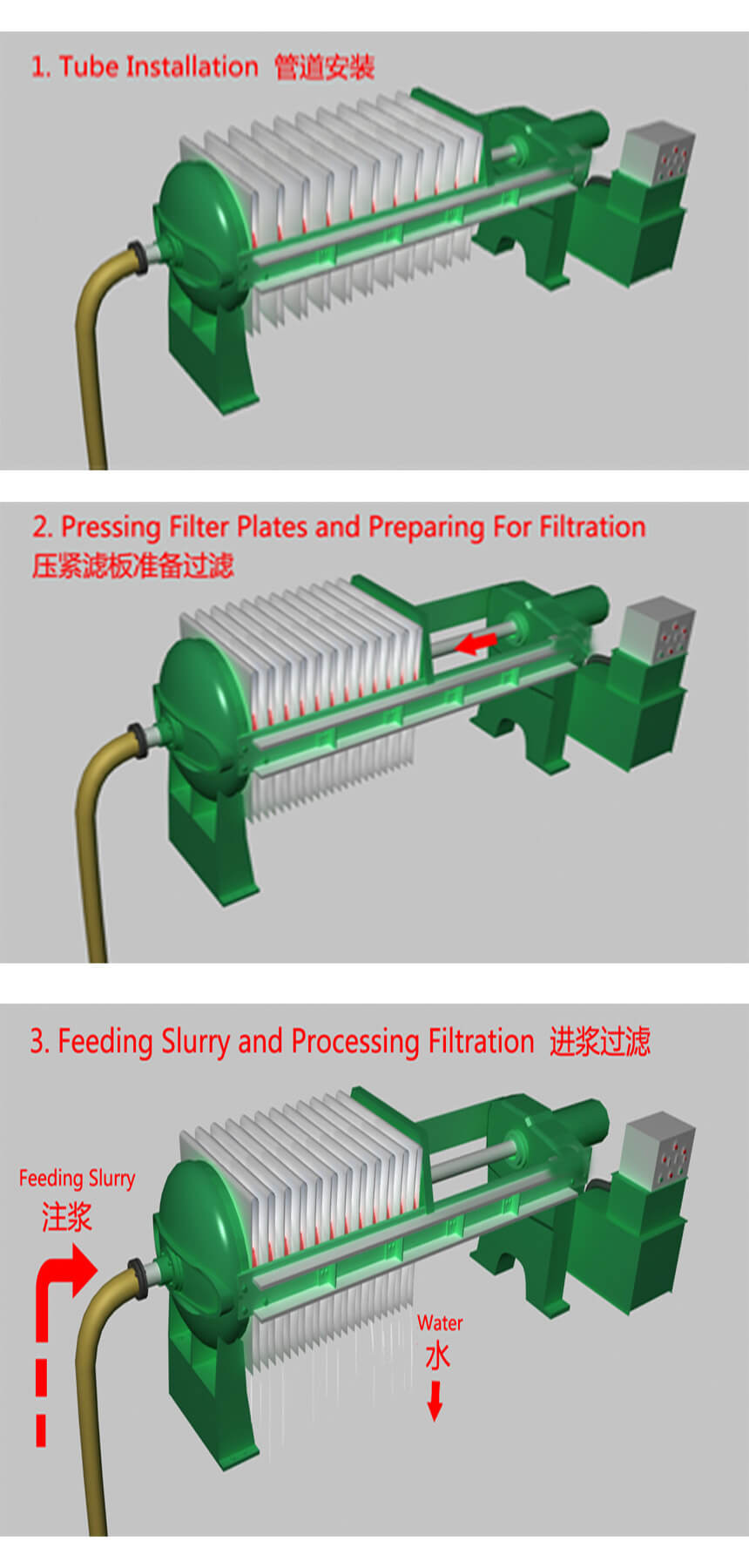

How Filter Press Work

Ceramic plunger pump transports the slurry into the filter press from the feeding head, the chambers created by the plates are filled up with the slurry, the cloth (specifically developed for each material) and the high pressure dry the cakes, faster and better. The clean water is discharged into water collector, ready to be reused, and the cakes can now be disposed of easily.

Filter Press Application:

Widely applied in Mining, Waste water Treatment(Ceramic, marble, granite, glass and so on) , Kaolin, Clay, Sand Washing and other solid-liquid separation.

Filter Press Technical Parameters:

Model | Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) L*W*H | Weight (kg) |

WYB-650 | 27 | Φ650 | 50 | 3 | 40 | 367 | ≤1.5 | 3950*1150*1170 4800*1150*1170 5800*1150*1170 | 2500 |

40 | 60 | 546 | 2700 | ||||||

54 | 80 | 725 | 3000 | ||||||

Plates quantity could be added or reduced according to customers' requirements. | |||||||||

1.Q: Can you provide us the detailed drawing?

Yes, we can provide you the drawing after have made the prepayment.

2.Q: Are you a manufacturer or a trader?

We're a professional and experienced manufacturer located in Shanghai.

3.Q: Can you accept OEM?

Yes, we can produce the machinery totally according to your design standard.

4Q: How about the delivery time?

Normally 10-30 working days after prepayment, and we promise we will make the delivery as soon as we can.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.