The Small Manual Jack Sewage Sludge Press Filter is a compact and user-friendly device designed for the treatment of sewage sludge. It operates with a manual jack mechanism for easy and efficient sludge pressing.

The Horizontal Electric Hydraulic Recessed Plate Filter Press is an advanced filtration equipment that operates horizontally and is driven by electric and hydraulic power. It features recessed plates for efficient filtration.

Lead Time:

according to the machine model and quantProduct Origin:

chinaShipping Port:

xiamenPayment:

T/T, LC at sightColor:

customizedHorizontal Electric Hydraulic Recessed Plate Filter Press

The Horizontal Electric Hydraulic Recessed Plate Filter Press offers a reliable and efficient filtration solution for various industrial processes. The horizontal design provides stability and ease of operation, while the electric hydraulic system ensures precise control and consistent performance.

The recessed plates increase the filtration area and enhance the filtering effect, allowing for the separation of solids and liquids with high accuracy. This makes it suitable for applications such as wastewater treatment, sludge dewatering, and chemical processing.

With its robust construction and advanced technology, the Horizontal Electric Hydraulic Recessed Plate Filter Press helps industries improve productivity, reduce waste, and meet environmental standards.

Filter Press Characteristic:

1. The main parts of filter press is made of cast steel.The filter plates are made of high intensity HDPE, which could sustain high feeding pressure, the highest value could be 2.0Mpa.

2. The hydraulic parts adopting the contact meter to maintain the pressure automatically, saving labor cost, improve the working efficiency.

3. The machine structure is simple and reasonable, easy installation and maintenance.

Filter Press Application:

Mining, Waste water Treatment(Ceramic, marble, granite, glass and so on) , Kaolin, Clay, Sand Washing and other solid-liquid separation.

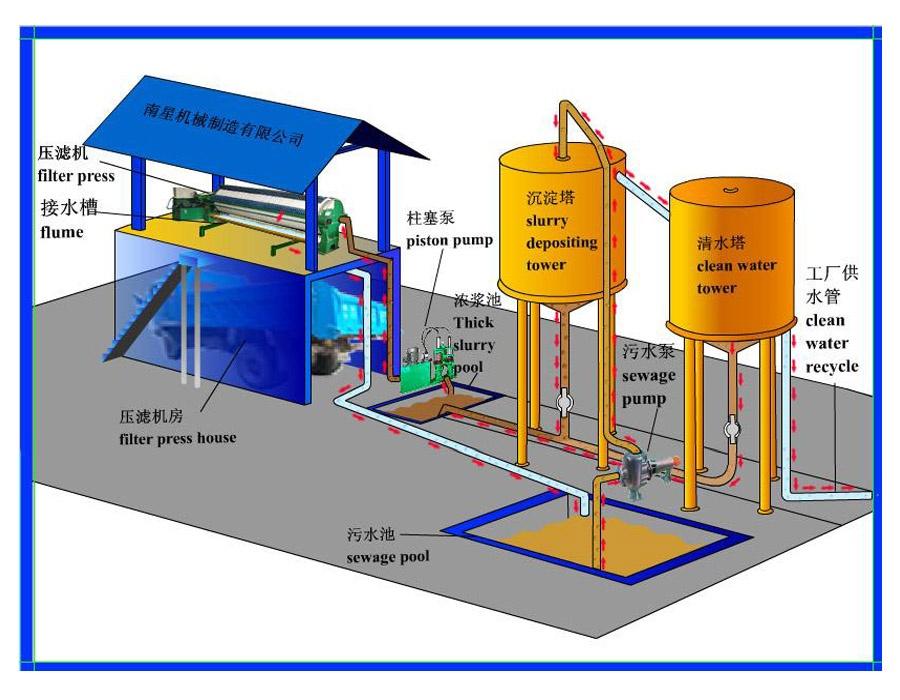

How Filter Press Work

Feeding pump transports the slurry into the filter press from the feeding head, the chambers created by the plates are filled up with the slurry, the cloth (specifically developed for each material) and the high pressure dry the cakes, faster and better. The clean water is discharged into water collector, ready to be reused, and the cakes can now be disposed of easily.

Filter Press Technical Parameters:

Model | Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) L*W*H | Weight (kg) |

WYB-450 | 2.5 | Ф380 | 40 | 3 | 10 | 25 | ≤1.5 | 2000*650*850 2500*650*850 | 800 |

5 | 20 | 50 | 900 | ||||||

WYB-550 | 5 | Ф550 | 50 | 3 | 10 | 66 | 2100*900*1100 | 1000 | |

10 | 20 | 132 | 2600*900*1100 | 1100 | |||||

Plates quantity could be added or reduced according to customers' requirements. | |||||||||

In 2012, Relying on the advantages of Fujian Nan’an Machineries manufacturing base and optoelectronic information industry base, we founded another company Fujian Nanxing Environmental Technology Co., Ltd. invest heavily for new factory and new equipments, put into use in 2014.Through standardized and scientific management, we satisfies customers with the products and service better and better, creating more and more value for customers.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.