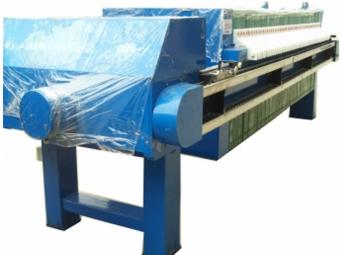

Slurry Plate Chamber Filtering Machine Press Filter

The Slurry Plate Chamber Filtering Machine Press Filter offers a reliable and effective solution for handling various types of slurries. The plate chamber design allows for a larger filtration area and better distribution of pressure, resulting in improved filtration efficiency and quality.

This machine is engineered to withstand the rigors of continuous operation and handle high-viscosity slurries with ease. Its robust construction and advanced filtration technology make it suitable for a wide range of industries, including mining, wastewater treatment, and chemical processing.

With its ability to separate solids from liquids effectively, the Slurry Plate Chamber Filtering Machine Press Filter helps reduce waste, increase productivity, and meet environmental regulations.

Filter Press Characteristic:

1. Strengthen polypropylene filter plates and flame are made through mold pressing.

2. Adopt hydraulic pressing with the maximum pressure pressure of 25Mpa and automatic pressure maintaining by using electrical connecting pressure gauge.

3.PLC control system, automatic open the plates one by one, open and close the water collector.

Filter Press Application:

Square filter plates are widely used in Food, Chemical, Dyeing, Leather, Mining (Aluminium, Bauxite, Copper, Iron) and Electroplate.

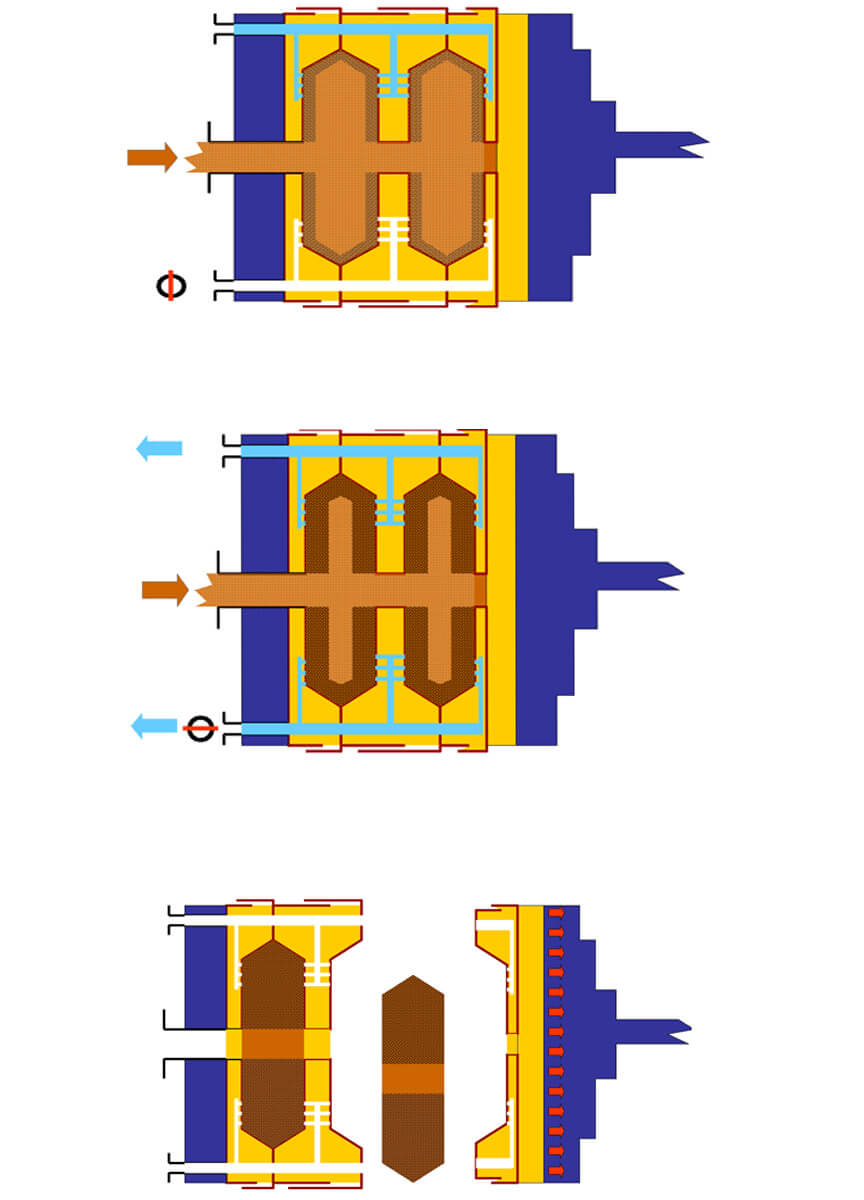

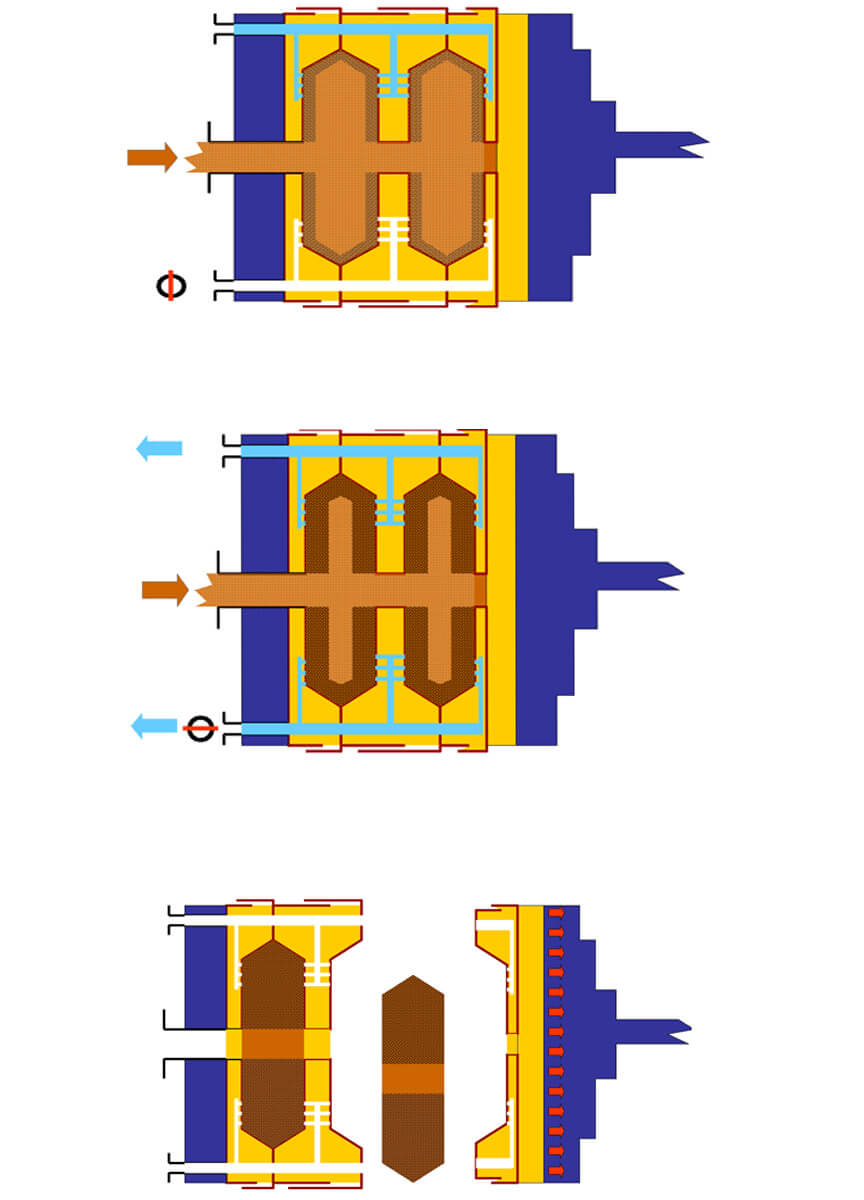

Filter Press Working:

The slurry is sent by slurry pump to chambers which formed by filter plates. Then filtrating media (filter cloth) separates solid and liquid. After the filtration finished, stopping the feeding, releasing the slurry pressure, press the returning button, shifting the plates automatically.

Filter Press Technical Parameters:

Hydraulic Chamber Filter Press With Square Plates

Model | Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) L*W*H | Weight (kg) |

NX-630 | 16 | 630*630 | 50 | 1.5 | 26 | 200 | ≤1.0 | 2790*1020*1200 | 1320 |

20 | 32 | 250 | 3096*1020*1200 | 1400 |

25 | 40 | 313 | 3504*1020*1200 | 1540 |

NX-800 | 50 | 800*800 | 60 | 1.5 | 50 | 750 | ≤1.0 | 4794*1246*1325 | 3140 |

60 | 60 | 900 | 5404*1246*1325 | 3470 |

70 | 70 | 1050 | 6014*1246*1325 | 3950 |

NX-1000 | 50 | 1000*1000 | 60 | 3.0 | 30 | 750 | ≤1.0 | 3984*1500*1555 | 4590 |

60 | 36 | 900 | 4350*1500*1555 | 4800 |

70 | 42 | 1050 | 4716*1500*1555 | 5160 |

80 | 48 | 1200 | 5082*1500*1555 | 5440 |

Plates could be added or reduced according to customer's requirements.

Pre-sale service:

1.Your inquiry will be replied within 8 hours.

2.Help you to select suitable model

3. Spare parts are in stock

After-sale service:

1.Provide 12 months warranty period and you will have our technology support forever

2.Engineering available to offer the service to your machinery oversea。

English

English  français

français español

español português

português العربية

العربية Melayu

Melayu ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia

IPv6 network supported

IPv6 network supported