The Small Manual Jack Sewage Sludge Press Filter is a compact and user-friendly device designed for the treatment of sewage sludge. It operates with a manual jack mechanism for easy and efficient sludge pressing.

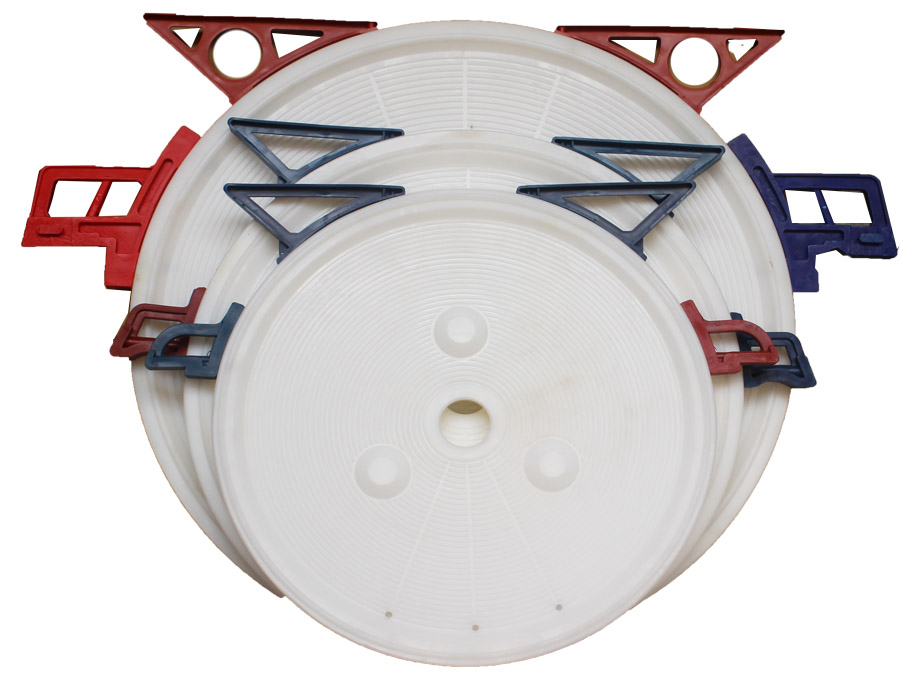

The PE Filter Plate Hydraulic Chamber Cast Steel Filter Press is a high-performance filtration device that combines a PE filter plate with a hydraulic chamber and cast steel construction. This cast steel filter press is special for shifting several plates by one time, some model could be five by one, some could be three by one.

Lead Time:

according to the machine model and quantProduct Origin:

chinaShipping Port:

xiamenPayment:

T/T, LC at sightColor:

customizedPE Filter Plate Hydraulic Chamber Cast Steel Filter Press

The PE Filter Plate Hydraulic Chamber Cast Steel Filter Press provides efficient and reliable filtration solutions. The PE filter plate offers excellent chemical resistance and durability, while the hydraulic chamber ensures precise and controlled pressure application.

The cast steel construction gives the filter press enhanced strength and stability, allowing it to handle heavy-duty filtration tasks in various industrial settings. This equipment is designed to deliver consistent filtration performance and long service life.

Whether in the mining, chemical, or wastewater treatment industries, the PE Filter Plate Hydraulic Chamber Cast Steel Filter Press is a trusted choice for achieving effective solid-liquid separation and improving process efficiency.

Filter Press Characteristic:

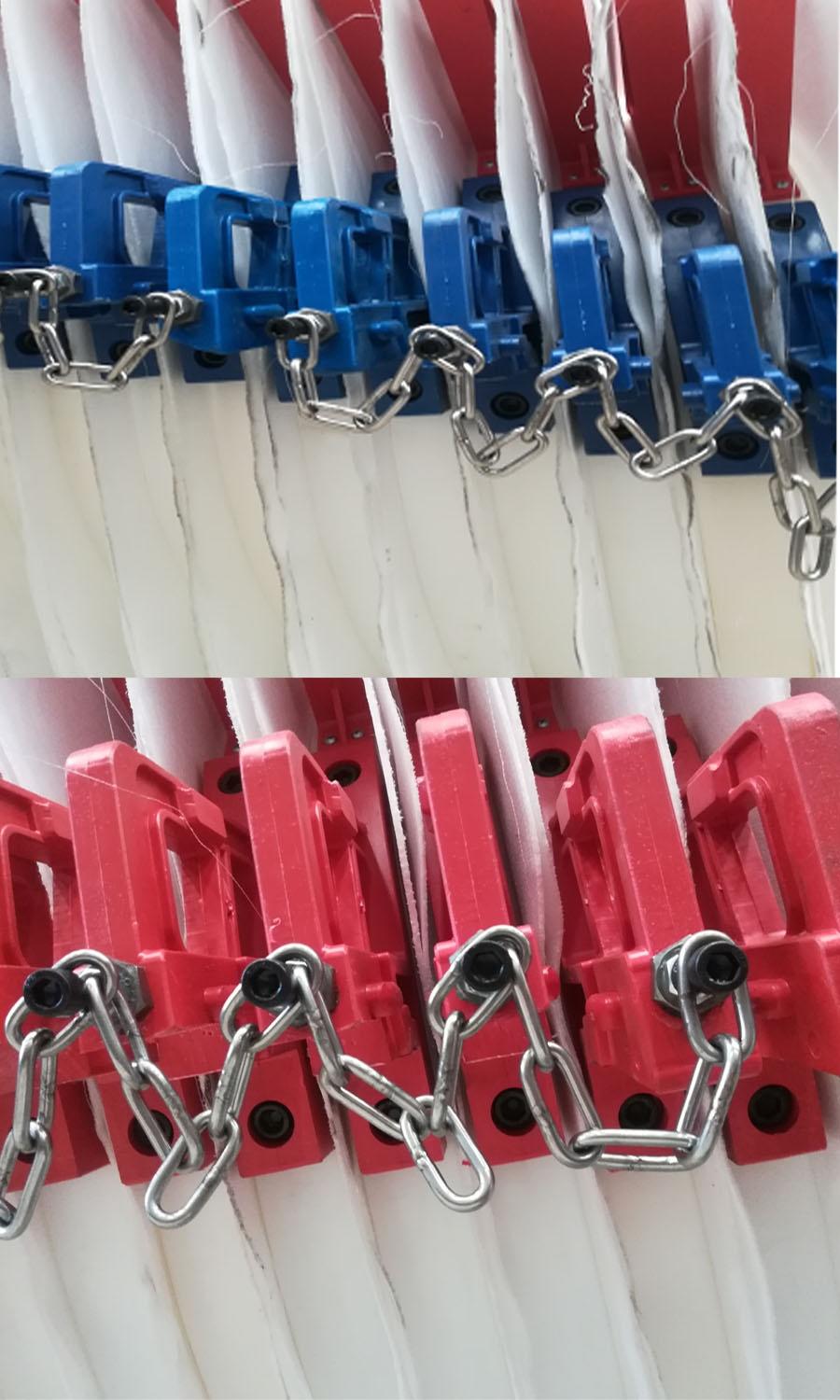

Filter Plate has mountain and valley design, which could high efficient prevent slurry spout.

According to the model, the automatic plate open device could shift plates 5pcs by one shift and 3pcs by one shift.

3. Main structure is made of cast steel and raw PE material, which let filter press sustain high feeding pressure.

Technical Parameters:

Model | Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) L*W*H | Weight (kg) |

K5ZWYB-800 | 45 | Ф750 | 55 | 4 | 50 | 604 | ≤1.5 | 5800*1400*1500 | 3900 |

72 | 75 | 906 | 7300**1400*1500 | 4400 | |||||

K5ZWYB-1000 | 106 | Ф920 | 60 | 4 | 80 | 1600 | 7700*1500*1600 | 7000 | |

125 | 95 | 1900 | 8600*1500*1600 | 7200 | |||||

Plates quantity could be added or reduced according to customers' requirements. | |||||||||

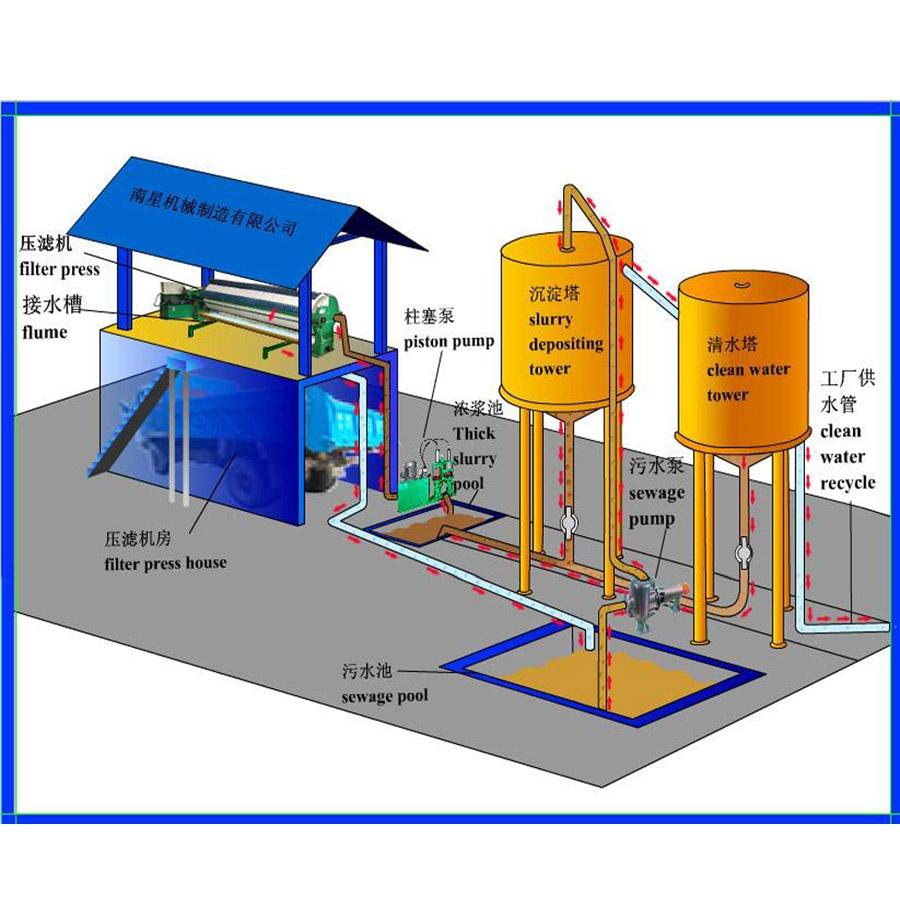

Filter Press Working Flow Chart:

The slurry will be transported to the filter press chambers, filter press do solid liquid separation, after that, the solid will be removed, clean water could be recycled by the factory.

Our products are famous for its advanced technology, reliable quality and stable operation, gaining the great reputations and supports from our customers. Our company is the main machineries supplier for clay project of Dalian Insulator Group Co., Ltd., Fujian Guanfu Modern Household Wares Co.,Ltd., Fujian Jinjiang Wanli Ceramics Industry Co., Ltd., Huihuang Plumbing Group Co. ,Ltd. etc. For the stone wastewater treatment, our company is also the tier one suppliers for stone wastewater treatment of Liven Stone, Xishi Group, Kangli Stone Group, Huahui Stone etc. What’s more, our products are the environmental products certified by National Environmental Protection Association, widely used in ceramic, stone, sand washing, mining, electroplating, chemical, leather, food etc.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.